Product Details

Boron carbide (B4C) Features:

1. Nano boron carbide powder possesses high purity, narrow range particle size distribution, larger specific surface area and so on;

2. The melting point of nano B4C is up to 2350oC, boiling point higher than 3500℃ hardness up to 9.3, flexural strength ≥ 400Mpa;

3. B4C nanoparticle does not react with acid and alkali solution. It has high chemical potential and is one of the most stable materials to acid. Also, it has properties of anti-oxidation, high temperature resistant, high strength, high grinding efficiency, high hardness, high elastic modulus, high wear-resistant, and good self-lubrication characteristics;

4. Boron carbide nanoparticle has a larger thermal neutron capture cross section, with excellent neutrons absorption property and good anti-radiation performance

Boron carbide Specifications:

|

Item |

Purity |

APS |

SSA |

Color |

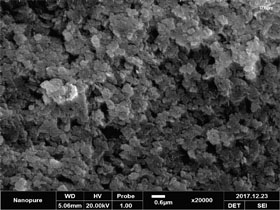

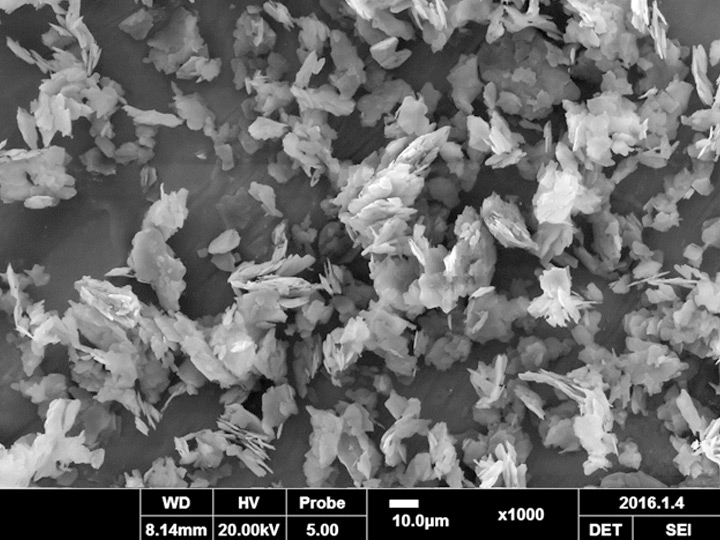

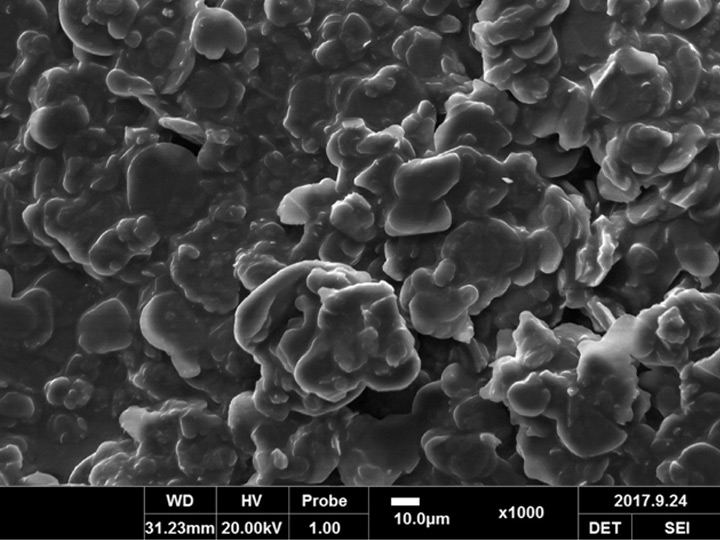

Morphology |

Zeta Potential |

Bulk Density |

|

B4C Nanoparticles |

>99% |

50nm |

42m2/g |

White |

hexagonal |

-26mV |

0.1g /cm3 |

Boron carbide Applications:

1) Be used in the field of fine abrasives: as grinding media for materials levigating e.x. be used to burnish,grind,polish and bore a hole on hard materials such as precious stones, ceramics, cutting tools, bearings,and carbide grinding etc.;

2) Be widely used in the field of industrial ceramic materials e.x. to produce blasting nozzles, seal rings, nozzles, bearings, mud pump plunger the pestle and rocket launchers, warships, helicopters ceramic coating;

3) Nano B4C has a proper standing in the area of shielded and control materials. It is the best material for controlling and shielding nuclear reactor the It is safe guareente in the nuclear industry;

4) Be used to produce bulletproof armor which is suitable for lightweight bulletproof armor e.x. be used in aircraft, vehicles, ships and for protection of the human body;

5) Be used to produce alloy powder so as to improve the life of the mechanical component;

6) Advanced Refractory materials: precision measuring element such as high-precision nozzles, seal rings and other fine engineering ceramics.

Boron Carbide Nanopowder Storage Conditions:

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the product should be avoided under stress.

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates