Effect of B4C abrasive mixed into dielectric fluid on electrical discharge machining

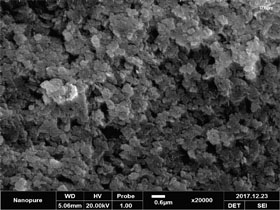

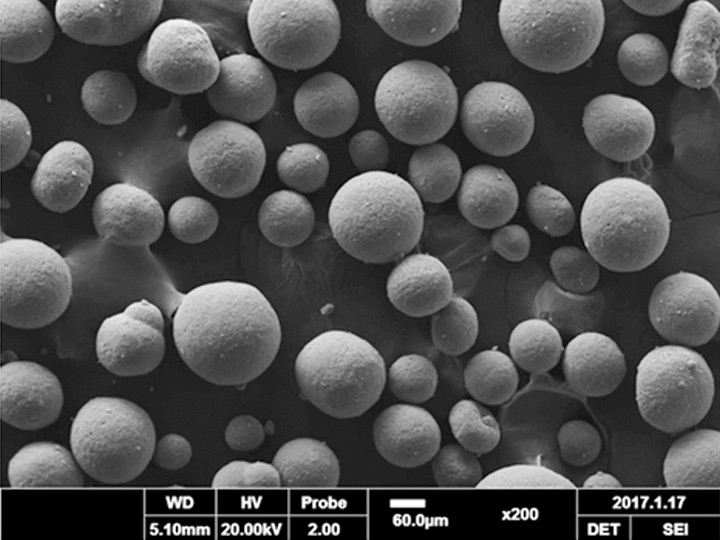

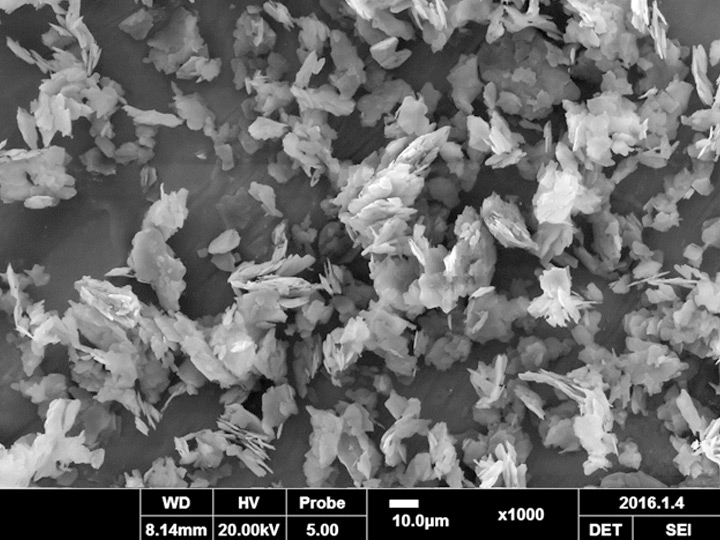

The present study investigates the effectiveness of abrasive-mixed EDM of titanium alloy. Taguchi method has been employed to optimize the output response of material removal rate, tool wear rate, wear rate and surface roughness for the machining of titanium alloy using the powder-mixed electrical discharge machining. In this study, abrasive particles of boron carbide (B4C) have been added to the kerosene oil which acts as a dielectric fluid. It has been found that material removal rate is increased and tool wear rate is reduced with the addition of B4C powder and surfactant in the dielectric fluid. Statistical results of ANOVA showed that material removal rate is significantly influenced by abrasive concentration and pulse on time in machining of blind holes with abrasive-mixed electric discharge machining on titanium alloy. Peak current has a significant effect on tool wear rate, and pulse on time has a significant effect on wear ratio. Further, it has been also concluded that abrasives concentration, pulses off time and peak current have shown a significant effect on surface roughness.

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates