Microstructure and Abrasive Wear Behavior of Copper–Boron Carbide Nanocomposites

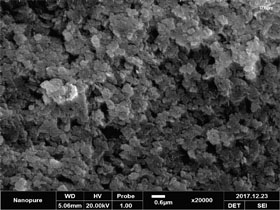

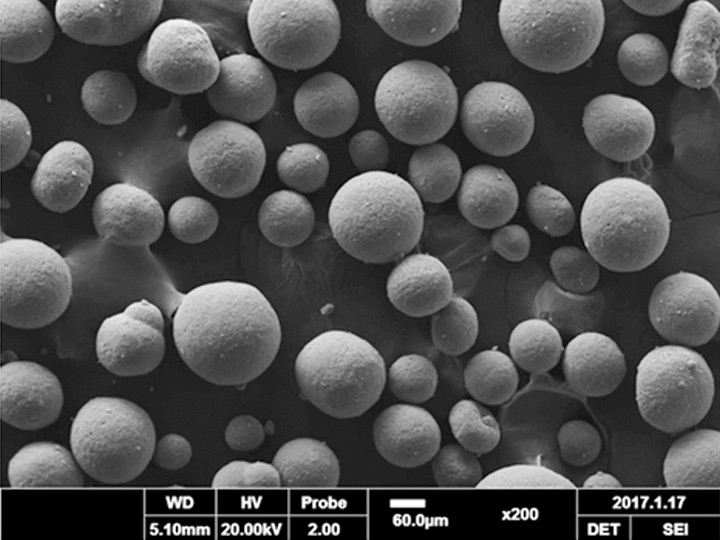

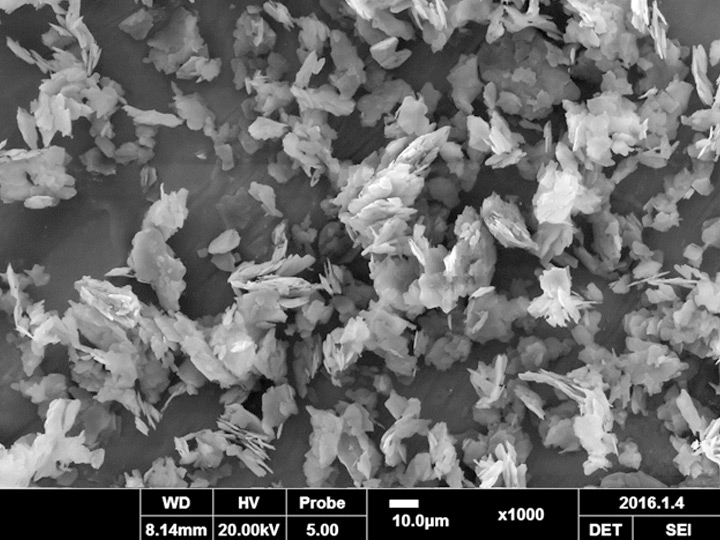

The effects of B4C nanoparticle reinforcements with an average size of 50 nm on the abrasive wear performance and microstructure of Cu nanocomposites were examined. Various combinations of Cu–B4C nanocomposites were synthesized by solid state powder metallurgy technique. Abrasive wear experiments were carried out by sticking the abrasive sheets of 400 grit silicon carbide on the disc of pin-on disc-wear tester. Pins of unreinforced Cu and Cu nanocomposites were pressed and rotated against silicon carbide abrasive sheets under dry sliding conditions at different loading conditions. Addition of nano-B4C in Cu matrix significantly enhances the hardness of the nanocomposites which in turn increases the wear resistance of nanocomposites. The nanocomposites with 1.5 wt% of B4C possess the superior microhardness and maximum wear resistance property. Morphology of worn out surfaces were explored by scanning electron microscopy.

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates