h boron nitride

Sources:nanopure | Release date:

2018-11-28

| Browsing volume:

Key words:h boron nitride

Diamond is a wide bandgap semiconductor that can work at high temperatures and resist very high electric fields. It endures harsh environments through its physical stability and conducts heat very well. These properties make diamond suitable for the fabrication of unique electronic devices. In particular, diamond field effect transistors (FETs) have promising applications, including high-power converters for trains and electric vehicles and high-power high-frequency amplifiers for telecommunications and radar. Although high mobility is desirable for these applications, it has been difficult to achieve in diamond FETs particularly when the carrier density is high. The low mobility is most probably due to fixed and trapped charges in the non-ideal amorphous gate dielectric and at the dielectric/diamond interface. Here, we report on diamond FETs with monocrystalline hexagonal boron nitride (h-BN) as a gate dielectric. Thanks to the low density of charged impurities in monocrystalline h-BN, we obtained unprecedentedly high mobilities (>300 cm2 V−1 s−1) for moderately high carrier densities (>5 × 1012 cm−2). The resulting minimum sheet resistance was exceptionally low (<3 kΩ). Our results show that a heterostructure consisting of monocrystalline h-BN and diamond is an excellent platform with which to manufacture high-performance electronic devices.

Diamond has a number of electronic properties that are well suited to power electronics and high-power radio-frequency applications.1–4 For instance, it has a wide bandgap and high breakdown electric field, and it has been used to make field effect transistors (FETs) that operate at high temperatures (400 °C)5 and high breakdown source-drain voltages (2000 V).6 It also has high intrinsic carrier mobility, which makes it potentially suitable for high-performance devices. In particular, high carrier mobility enables the on-resistance and the switching time to be reduced, which in turn reduces the conduction and switching losses of high-power switching devices. High carrier mobility also benefits the operation of high-power radio-frequency devices. Here, the generally accepted intrinsic mobilities of diamond are as high as 4500 cm2 V−1 s−1 for electrons and 3800 cm2 V−1 s−1 for holes at room temperature.7 Recent cyclotron resonance experiments on ultrapure CVD diamonds have indicated even higher mobilities: 7300 cm2 V−1 s−1 for electrons and 5300 cm2 V−1 s−1 for holes.8 These values are much larger than those of silicon, germanium,9 silicon carbide,1 and gallium nitride10 (HEMT11). The high intrinsic mobility of diamond is due to its high-velocity acoustic phonons, which only weakly scatter carriers.

However, high carrier mobility has been difficult to realize in diamond FETs, especially when the carrier density is high. The reported mobilities are mostly lower than 200 cm2 V−1 s−1.12–25 Although higher mobilities have been indicated in a few reports,26–29 the carrier density was less than 1 × 1012 cm−2 and the sheet resistance was high (>10 kΩ). The low mobility and low carrier density were attributed to defects in the amorphous gate dielectric, such as Al2O3, used in the FETs. Here, fixed and trapped charges in the gate dielectric and at the dielectric/diamond interface cause Coulomb scattering of carriers, which reduces mobility.30 Furthermore, high gate leak current,17,19,23–25 presumably caused by trap-assisted tunneling,31 limits the applicable gate electric field and attainable carrier density.

Single-crystalline hexagonal boron nitride (h-BN) is promising as an alternative gate dielectric. Single-crystalline h-BN has few charged impurities, and a flat surface with no dangling bonds can easily be obtained by cleaving it. Indeed, the carrier mobility of graphene on an h-BN substrate has been shown to be much higher than that of graphene on a SiO2 substrate.32 As it is a flat and charge-free substrate, h-BN is considered indispensable for the study of graphene physics.33–37 Furthermore, the breakdown electric field of h-BN is as high as 12 MV cm−1 for the direction perpendicular to the layers.38 These properties make h-BN suitable for use as a gate dielectric in FETs with very high mobility and carrier density.

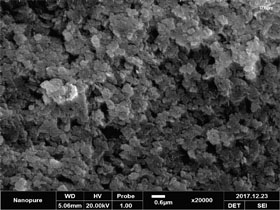

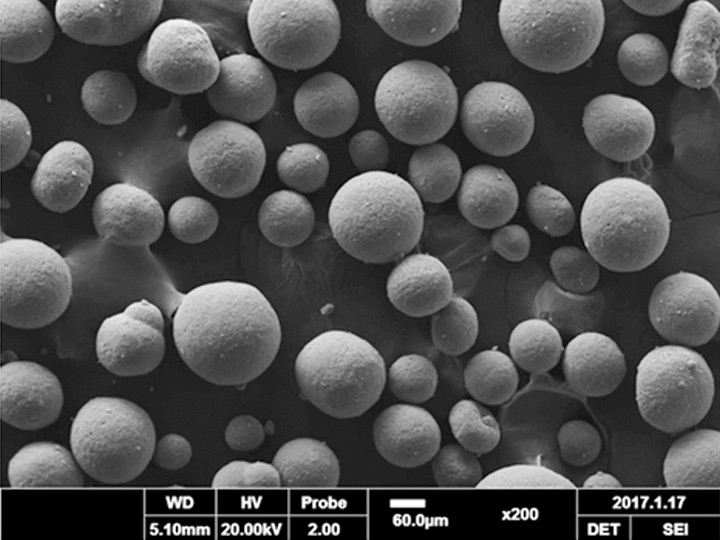

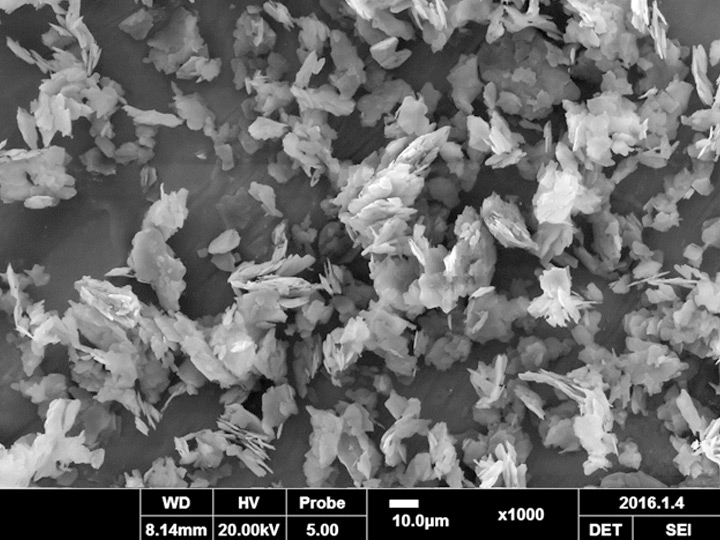

In this study, we fabricated diamond FETs with a monocrystalline h-BN as a gate dielectric. The device structure is shown in Fig. 1(a). The diamond surface is (111)-oriented and hydrogen-terminated [Fig. 1(b)]. The hydrogen termination reduces the density of surface states and also makes the hole accumulation more favorable because of the resulting upward shift of the energy bands.39,40 A thin monocrystalline h-BN flake [Fig. 1(c)] is laminated on the diamond surface. To fabricate this h-BN/diamond structure, we used the Scotch tape exfoliation technique developed for van der Waals heterostructures of graphene and other two-dimensional materials32,35 (see “Device fabrication” and Fig. S1 of the supplementary material for details of the device fabrication). The longest edge of the h-BN flake was aligned to the [1¯10][1¯10] direction of diamond. Ohmic contacts for the source and drain electrodes were produced by deposition of Ti/Pt and subsequent annealing to form TiC. A Hall bar structure was used for the four-probe and Hall measurements, from which the carrier density and mobility were evaluated. An optical microscope image of a fabricated device is shown in Fig. 1(d).

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products