hardness of boron carbide

Sources:nanopure | Release date:

2018-10-24

| Browsing volume:

Key words:hardness of boron carbide

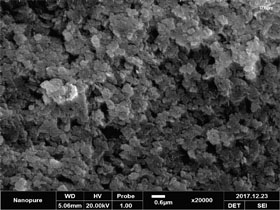

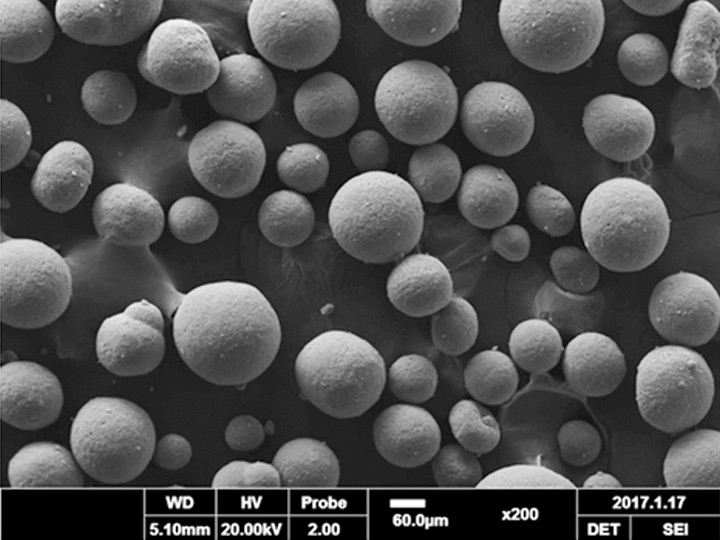

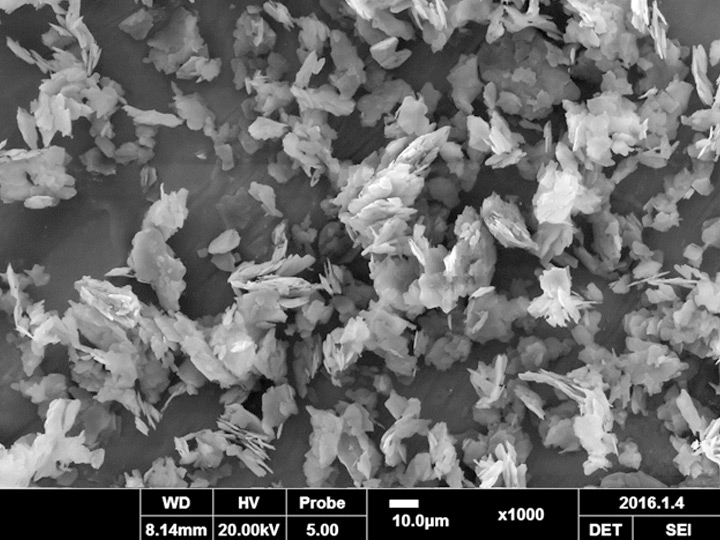

e deposited amorphous thin films of boron carbide by pulsed laser

deposition using a B 4 C target at room temperature. As the laser

fluence increased from 1 to 302J/cm 2 , the number of 0.25–502μm

particulates embedded in the films decreased, and the B/C atomic ratio

of the films increased from 1.8 to 3.2. The arrival of melt droplets,

atoms, and small molecular species depending on laser fluence appeared

to be involved in the film formation. In addition, with increasing

fluence the nanoindentation hardness of the films increased from 14 to

3202GPa. We believe that the dominant factor in the observed increase in

the films’ hardness is the arrival of highly energetic ions and atoms

that results in the formation of denser films.

Previous:boron carbide formula

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products