Boron Carbide Nanopowder

Sources:nanopure | Release date:

2018-06-11

| Browsing volume:

Key words:Boron Carbide Nanopowder

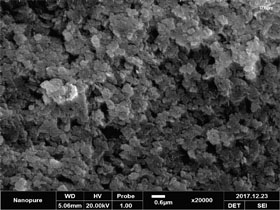

Boron carbide nanopowder possesses high purity, narrow range particle size distribution, larger specific surface area. The melting point of boron carbide nanopowder is up to 2350°C, boiling point higher than 3500℃ hardness up to 9.3, flexural strength ≥ 400Mpa. B4C nanoparticle does not react with acid and alkali solution. It has high chemical potential and is one of the most stable materials to acid. It has properties of anti-oxidation, high temperature resistant, high strength, high grinding efficiency, high hardness, high elastic modulus, high wear resistant, and good self-lubrication characteristics.

Properties

Extreme hardness

Difficult to sinter to high relative densities without the use of sintering aids

Good chemical resistance

Good nuclear properties

Low density

Applications

Boron Carbide with its high hardness is widely used in polishing, lapping and drilling of hard metals, corundum, sapphire, glass and ceramics, as well as a loose abrasive in cutting applications such as water jet cutting. It can also be used for dressing diamond tools. Ware resistance coating due to its high hardness and excellent ware resistance coating of carbide boron nitride have been developing. Wear parts such as blasting nozzles, wire-drawing dies, powdered metal and ceramic forming dies. Nuclear applications such as reactor control rods and neutron absorbing shielding.

Bulletproof Materials

Boron carbide fibers and fiber composites may be used in the manufacture of ballistic materials for protective, durable and light weight body armor. The distinct characteristics of advanced boron carbide materials made from boon carbide ceramic fibers light weight, high hardness, wear and corrosion resistant–offer advantages over conventional materials such as plastics and metals. The carbide ceramic is used in tank armor and bulletproof vests.

Boron carbide ceramics fibers may be manufactured in large volume and formed into various shapes and sizes to allow cost effective body armor production along with custom molding in massive quantities. Also, boron carbide ceramics fibers may be formed as composites to facilitate various applications.

Vehicle/ Aircraft Armor Systems:

Boron Carbide is a material used in tank armors and bulletproof vests and as well as numerous industrial applications. Hardness of boron carbide and silicon carbide is extremely high, and density is relatively low, making it an ideal material for bullet proof vest. It has good corrosion resistance, great mechanical strength under high temperature and excellent wear resistance. Boron carbide is also the most important ceramic material for ceramic armor.

Modern military equipment must be highly exile, rapid response and provide maximum safety. Ballistic protection is one such area. Boron carbide highest protection is one such area. Boron carbide highest protection levels at lowest possible weight. It have ballistic protection of aircraft. It also used for helicopter seats. Durable and light weight boron carbide ceramics fibers and fiber composites may be incorporated into aircraft protection systems for fixed wing and rotary type aircraft. Exemplary applications include panels, tiles, components, etc. comprising boron carbide ceramics fibers. Aircraft armor systems may be used to protect personnel and cargo areas, vital equipment, controls, and the like.

Boron Carbide

Boron Carbide

Automotive Industry:

Research &Development, design and manufacturing of custom design compact B4C production of boron carbide including nuclear grade and carbide alloys for high tech composite materials and engineering ceramics. Boron carbide fibers and fiber composites may be used in automobile manufacturing, as armor plating, in the vehicle body, in the construction of engine blocks, etc. For example, in one embodiment, an engine block may include a fiber composite comprising boron carbide fiber and aluminum metal.

Boron Carbide

Boron Carbide

Erosion Resistance Systems:

Boron carbide fiber reinforced composites may be used for brake pads to reduce wear and increase stoppage power in automobiles, motorcycles, aircrafts, etc. The brake pads in high speed cars wear off very fast. The use of a high modulus ceramic fiber, such as boron carbide, in brake pads can significantly prolong the life of brake pads. Boron carbide fiber can be used in any type of break pad by uniformly distributing short or long fibers in the pad matrix and thereby reinforcing.

Boron carbide abrasiveness

Hard coatings, such as boron carbide (B4C), can quickly polish the surface of the mating material during sliding contact. The abrasiveness of such coatings directly relates to their ability to polish and sharply decreases as sliding progresses. The abrasiveness also strongly depends upon the sharpness of the individual coating asperities. Various parameters influence the rate at which the abrasiveness decreases and therefore control the run-in process. Such coatings can serve as finite-life run-in coatings for specific applications such as gears. Boron carbide is a super hard abrasive material, next only to diamond and cubic boron nitride in hardness. it simply outclasses the conventional abrasive like aluminum oxide and silicon carbide with its superlative and cost effective performance.

Properties

Extreme hardness

Difficult to sinter to high relative densities without the use of sintering aids

Good chemical resistance

Good nuclear properties

Low density

Applications

Boron Carbide with its high hardness is widely used in polishing, lapping and drilling of hard metals, corundum, sapphire, glass and ceramics, as well as a loose abrasive in cutting applications such as water jet cutting. It can also be used for dressing diamond tools. Ware resistance coating due to its high hardness and excellent ware resistance coating of carbide boron nitride have been developing. Wear parts such as blasting nozzles, wire-drawing dies, powdered metal and ceramic forming dies. Nuclear applications such as reactor control rods and neutron absorbing shielding.

Bulletproof Materials

Boron carbide fibers and fiber composites may be used in the manufacture of ballistic materials for protective, durable and light weight body armor. The distinct characteristics of advanced boron carbide materials made from boon carbide ceramic fibers light weight, high hardness, wear and corrosion resistant–offer advantages over conventional materials such as plastics and metals. The carbide ceramic is used in tank armor and bulletproof vests.

Boron carbide ceramics fibers may be manufactured in large volume and formed into various shapes and sizes to allow cost effective body armor production along with custom molding in massive quantities. Also, boron carbide ceramics fibers may be formed as composites to facilitate various applications.

Vehicle/ Aircraft Armor Systems:

Boron Carbide is a material used in tank armors and bulletproof vests and as well as numerous industrial applications. Hardness of boron carbide and silicon carbide is extremely high, and density is relatively low, making it an ideal material for bullet proof vest. It has good corrosion resistance, great mechanical strength under high temperature and excellent wear resistance. Boron carbide is also the most important ceramic material for ceramic armor.

Modern military equipment must be highly exile, rapid response and provide maximum safety. Ballistic protection is one such area. Boron carbide highest protection is one such area. Boron carbide highest protection levels at lowest possible weight. It have ballistic protection of aircraft. It also used for helicopter seats. Durable and light weight boron carbide ceramics fibers and fiber composites may be incorporated into aircraft protection systems for fixed wing and rotary type aircraft. Exemplary applications include panels, tiles, components, etc. comprising boron carbide ceramics fibers. Aircraft armor systems may be used to protect personnel and cargo areas, vital equipment, controls, and the like.

Boron Carbide

Boron Carbide

Automotive Industry:

Research &Development, design and manufacturing of custom design compact B4C production of boron carbide including nuclear grade and carbide alloys for high tech composite materials and engineering ceramics. Boron carbide fibers and fiber composites may be used in automobile manufacturing, as armor plating, in the vehicle body, in the construction of engine blocks, etc. For example, in one embodiment, an engine block may include a fiber composite comprising boron carbide fiber and aluminum metal.

Boron Carbide

Boron Carbide

Erosion Resistance Systems:

Boron carbide fiber reinforced composites may be used for brake pads to reduce wear and increase stoppage power in automobiles, motorcycles, aircrafts, etc. The brake pads in high speed cars wear off very fast. The use of a high modulus ceramic fiber, such as boron carbide, in brake pads can significantly prolong the life of brake pads. Boron carbide fiber can be used in any type of break pad by uniformly distributing short or long fibers in the pad matrix and thereby reinforcing.

Boron carbide abrasiveness

Hard coatings, such as boron carbide (B4C), can quickly polish the surface of the mating material during sliding contact. The abrasiveness of such coatings directly relates to their ability to polish and sharply decreases as sliding progresses. The abrasiveness also strongly depends upon the sharpness of the individual coating asperities. Various parameters influence the rate at which the abrasiveness decreases and therefore control the run-in process. Such coatings can serve as finite-life run-in coatings for specific applications such as gears. Boron carbide is a super hard abrasive material, next only to diamond and cubic boron nitride in hardness. it simply outclasses the conventional abrasive like aluminum oxide and silicon carbide with its superlative and cost effective performance.

Relevant articles

- 2020-09-24 > Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111)

- 2020-09-24 > Hexagonal Boron Nitride as a Multifunctional Support for Engineering Efficient Electrocatalysts toward the Oxygen Reduction Reaction

- 2020-08-21 > Boron nitride nanotubes and nanosheets

- 2020-08-21 > A comprehensive analysis of the CVD growth of boron nitride nanotubes

- 2020-06-13 > One-dimensional hexagonal boron nitride conducting channel

- 2020-06-13 > Metal-Free Modified Boron Nitride for Enhanced CO2 Capture

- 2020-06-13 > Functionalizations of boron nitride nanostructures

- 2020-06-13 > Engineering spin defects in hexagonal boron nitride

- 2020-06-13 > Grain Dependent Growth of Bright Quantum Emitters in Hexagonal Boron Nitride

- 2020-06-13 > Process for manufacturing boron nitride agglomerates

Related products